Part Name: Printer Side Plate

Category: Computer Peripherals / Printers

Method: Precision Sheet Metal Fabrication

Description: Dim 9″x 12″ Material 5052 H32 .063 thick Finish. Black Anodize

Equipment Used: CNC Turret Press, Press Brake, Time Saver, Hager Press (PEM Insert), Blank & Pierce on Turret Press Form, Press Brake.

Seven different hardware part numbers for a total of 49.

500 to 2500 parts per year. As a fabricated part, there was no tooling charge (NREC).

Part Name: Amplifier Back Plate

Category: Electronic Controls / Audio

Method: Precision Sheet Metal Fabrication

Description: Dim 9″ x 18″

Material: 5052 H32 .063″ thick

Finish: Blue and Clear Anodize with Selective Screen Printing.

Equipment Used: CNC Turret Press, Press Brake, Time Saver, Part required 6 forming hits.

50 to 250 parts per year. Fabricated no tool charge (NREC).

Part Name: Amplifier Front Face

Category: Electronic/ Audio

Method: Precision Sheet Metal Fabrication

Description: 18″ X 4″ Material Aluminum Finish. Blue and Clear Anodize with Selective Screen Printing.

Equipment Used: CNC Turret Press, Press Brake, Time Saver (wide belt graining)

Part Name: Device Retainer

Category: Medical Device

Method: Precision Sheet Metal Fabrication / Weld

Description: Dim 6” x 5”

Material: 5052 H32 060 thick

Equipment Used: Turret Press, Press Brake, Hager Press (PEM inserts) Tapping, Weld and Grind.

Unit is made from 2 parts that are assembled and welded together. Grinding was done to seal up all corners after weld.

This part was onshored and reshored.

Part Name: Remote Printer Stand

Category: Computer Peripheral / Printer

Method: Precision Sheet Metal Fabrication / Low Cost Tool

Description: 11” X 6”

Material: CRS ANN 060 (16 ga )

Equipment Used: Flat Bed Laser, Press Brake, Some Custom Tooling.

Note: Combined Laser, Sheet Metal Fabrication with Stamping to produce part most economically in production runs of 3000-5000 per year. (short runs)

Part Name: Transformer Mounting Bracket

Category: Electrical Controls

Method: Sheet Metal Fabrication

Description: 7” x 3” x 2”

Material: 5052 H32 .063 Thick

Finish: Red Anodize

Equipment Used: Turret Press, Press Brake, Hager Press for PEM inserts.

Very short run sheet metal fabrication.

Part Name: Printer Chassis

Category: Printers / Gaming

Method: Sheet Metal Fabrication

Description: 18” X 6”

Material: CRS ANN 047 (18 ga)

Finish: Black Zinc

Equipment Used: 100 ton Punch Press for blanking, 60 ton Punch Presses for Forming, Hager Press for PEM insertion.5000-10000 per order. Set up dedicated work cell to handle volume.

This part was onshored and reshored.

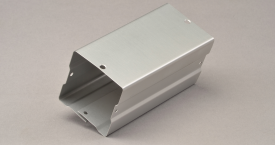

Part Name: Case, Aluminum

Category: Electronic Controls

Method: Short Run Metal Stamping

Description: 6” X 2” X 2”

Material: 3003 H14 Aluminum

Finish: Clear Anodize

Equipment Used: Punch Press with Horn Die

Part Name: Steel Cases

Category: Electronic Controls

Method: Short Run Metal Stamping

Description: 6” X 2” X 2”

Material: 3003 H14 Aluminum

Finish: Clear Anodize

Equipment Used: Punch Press with Horn Die